🔧 This article is part of the FluidForce NZ Hydraulic Hose How-To & Troubleshooting Guides.

Explore step-by-step instructions, fitting advice, and safety best practices at our

Hydraulic Hose How-To Hub.

Why Is My Hydraulic Hose Leaking?

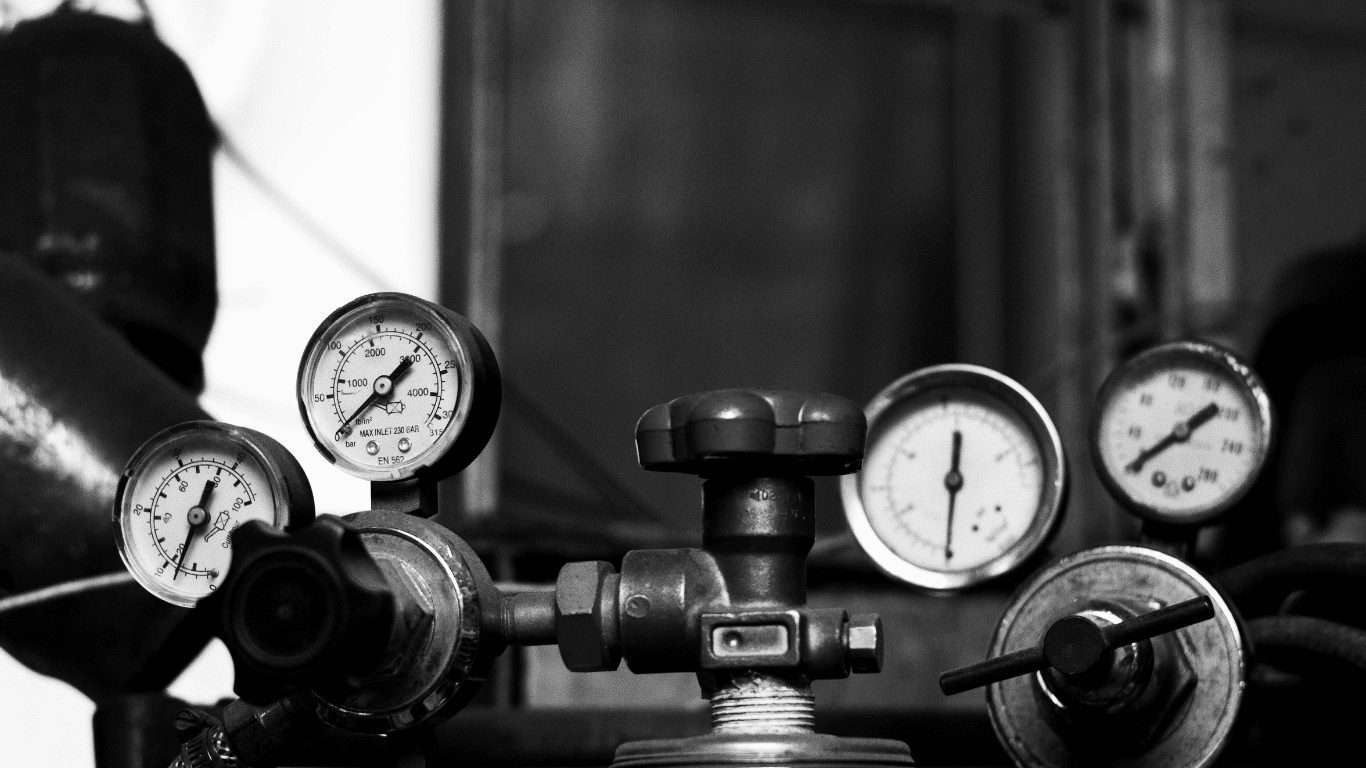

Hydraulic systems rely on precise pressure and tight connections. When leaks, blowouts, or fitting issues appear, quick and accurate troubleshooting can prevent major damage or downtime.

A leaking hydraulic hose can result from assembly errors, wear and tear, or contamination. Identifying the source quickly prevents costly oil loss and safety hazards.

Below are the most common causes and step-by-step checks to help you identify and fix problems safely.

Loose or improperly torqued fittings – Connections may vibrate loose or weren’t tightened to spec.

Damaged hose cover or reinforcement – Cuts, abrasion, or crushing can allow oil to escape through the braid.

Aged or hardened rubber – Over time, the inner tube can crack, especially with heat exposure.

Contaminated or incompatible fluid – Chemical breakdown from wrong oil types can attack hose materials.

Over-pressurisation – Pressure spikes may rupture weak sections or seals.

Clean the hose and fitting area, then pressurise the system to visually locate seepage.

Check for weeping around ferrules or crimp ends — this indicates internal tube failure.

Examine fitting seat surfaces for cracks or scoring.

Need more help?

If you can’t find the information you need, or want help with your specific set up, get in touch.